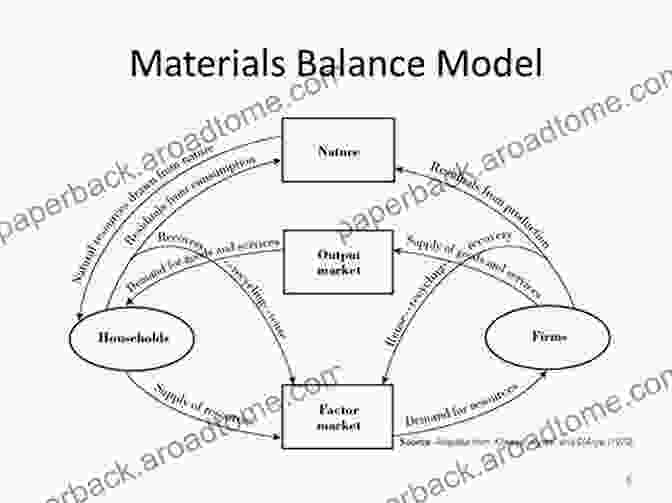

What Is The Material Balance Model: A Deep Dive into Process Analysis

The Material Balance Model (MBM) is a powerful tool used in process engineering and chemical engineering. It provides a structured framework for analyzing and understanding the flow of materials within a process or system. By applying the principles of conservation of mass, the MBM enables engineers to track and quantify the inputs, outputs, and transformations of materials throughout a process.

Basic Principles

The MBM is based on the fundamental law of conservation of mass, which states that mass can neither be created nor destroyed. In a process, the total mass of inputs must equal the total mass of outputs. This principle forms the foundation for the MBM equation:

Inputs - Outputs + Generation - Consumption = Accumulation

- Inputs: Mass entering the process

- Outputs: Mass leaving the process

- Generation: Mass created within the process

- Consumption: Mass destroyed or consumed within the process

- Accumulation: Change in mass stored within the process

Applications

The MBM has a wide range of applications in process engineering, including:

- Process Design: Optimizing process parameters to maximize efficiency and minimize waste.

- Process Troubleshooting: Identifying and diagnosing process inefficiencies or imbalances.

- Environmental Impact Assessment: Quantifying mass emissions and waste generation.

- Energy Analysis: Integrating mass and energy balances to optimize energy efficiency.

- Chemical Reactions: Modeling the stoichiometry and reaction rates of chemical processes.

Real-World Examples

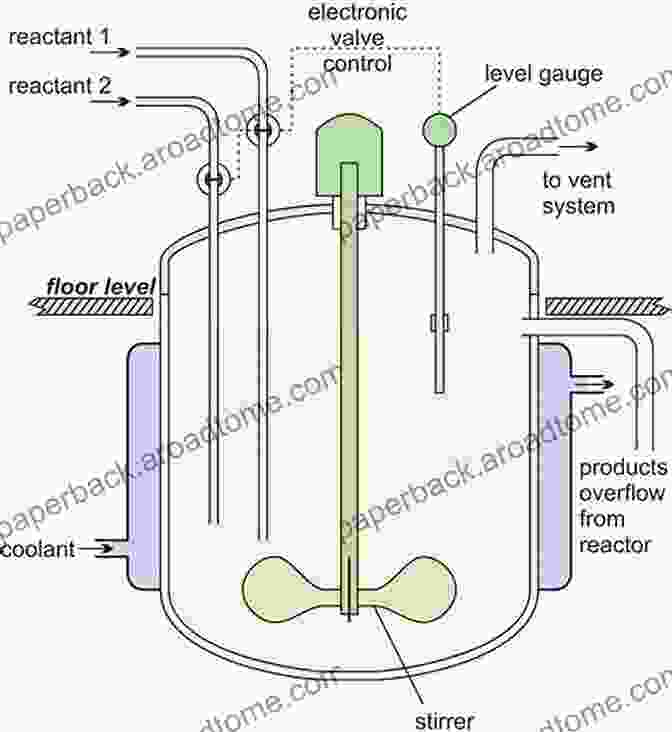

Consider the example of a chemical reactor where a reactant A is converted into product B. The MBM can be used to determine the mass flow rate of the reactant and product, as well as the conversion efficiency of the reactor.

In another example, a food processing plant uses the MBM to quantify the mass of raw materials entering the plant, the mass of finished products produced, and the mass of waste generated. This information is essential for optimizing production, minimizing waste, and meeting regulatory requirements.

Benefits of Using the MBM

- Improved process understanding

- Efficient process design

- Early detection of process inefficiencies

- Reduced environmental impact

- Optimized production and utility consumption

The Material Balance Model is a powerful tool that provides a systematic and quantitative approach to process analysis. By applying the principles of mass conservation, engineers can gain valuable insights into the flow of materials within a process, optimize process parameters, and enhance overall efficiency. As a fundamental tool in process engineering, the MBM plays a critical role in designing, troubleshooting, and optimizing processes across a wide range of industries.

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Joseph ConradFollow ·3.1k

Joseph ConradFollow ·3.1k Samuel BeckettFollow ·17.8k

Samuel BeckettFollow ·17.8k Adam HayesFollow ·16.2k

Adam HayesFollow ·16.2k Alan TurnerFollow ·16.3k

Alan TurnerFollow ·16.3k Ronald SimmonsFollow ·14.9k

Ronald SimmonsFollow ·14.9k Fernando PessoaFollow ·10.1k

Fernando PessoaFollow ·10.1k Brenton CoxFollow ·5.4k

Brenton CoxFollow ·5.4k Ray BlairFollow ·7.4k

Ray BlairFollow ·7.4k

Isaiah Powell

Isaiah PowellWisconsin Clinic Pilots Mobile Crisis Response System For...

MADISON, Wis. - A new mobile crisis...

Daniel Knight

Daniel KnightUnleash Your Creativity: A Masterclass in Fabulous Nail...

Embellish Your Fingertips with Captivating...

Clark Campbell

Clark CampbellDetect When You Are Being Emotionally Manipulated By...

Emotional manipulation is a subtle but...

Eli Brooks

Eli BrooksNeurological Disorders Papers: Dissociative Identity...

What is Dissociative...

Ricky Bell

Ricky BellAn Introduction to Islam for Jews: Unveiling the Tapestry...

A Bridge of Understanding: Exploring Islam for...

Octavio Paz

Octavio PazAchieving Longevity: The Complete Step-by-Step Guide to...

**** In the ever-evolving landscape of health...